Brian Sutton

Medical device and implant makers are feeling the squeeze when it comes to parts cleaning. OEM specs, global standards, and environmental rules keep tightening—while geometries get smaller and materials more diverse. If your washer, passivation tank, or chemistry recipe hasn’t changed in a few years, you may already be behind. Below are the six emerging…

Read MoreIn the aerospace industry, meeting stringent cleanliness standards is crucial for ensuring component reliability and performance. A well-formulated aqueous alkaline spray wash chemistry is essential for effectively removing tough contaminants such as grease, oils, BOE lube, Krytox, and fluorescent penetrant inspection (FPI) residues. If not properly removed, these residues can compromise the structural integrity, surface…

Read MoreAluminum is a popular material in industries like aerospace, automotive, and medical due to its lightweight and durable nature. However, cleaning aluminum parts can be tricky. Ultrasonic cleaners have emerged as an effective, non-abrasive solution for maintaining the integrity of aluminum surfaces. In this guide, we’ll cover everything you need to know about ultrasonic cleaner…

Read MoreMaintaining cleanliness in aerospace and aviation parts is crucial for safety, performance, and regulatory compliance. This article provides an in-depth look at effective cleaning methods, from ultrasonic cleaners to spray washers, ensuring your aircraft components meet the highest standards. Learn how proper cleaning can optimize aircraft reliability and precision while exploring JAYCO’s aerospace-approved solutions that…

Read MoreUltrasonic cleaning has become an essential part of many industries, from automotive to medical. By using sound waves to create cavitation bubbles, ultrasonic cleaners can remove contaminants from intricate and hard-to-reach areas, providing a deep clean that’s difficult to achieve with other methods. However, the effectiveness of an cleaning process doesn’t just depend on the…

Read MoreInsights R+W America faced significant issues with part discoloration during the cleaning process, risking the perceived quality of their precision couplings. Jayco’s JC 201C chemistry resolved those issues by eliminating streaks and burn marks, leading to brighter, more consistent parts without sacrificing cleaning effectiveness. Introduction R+W America is located in West Chicago, IL. Originally founded…

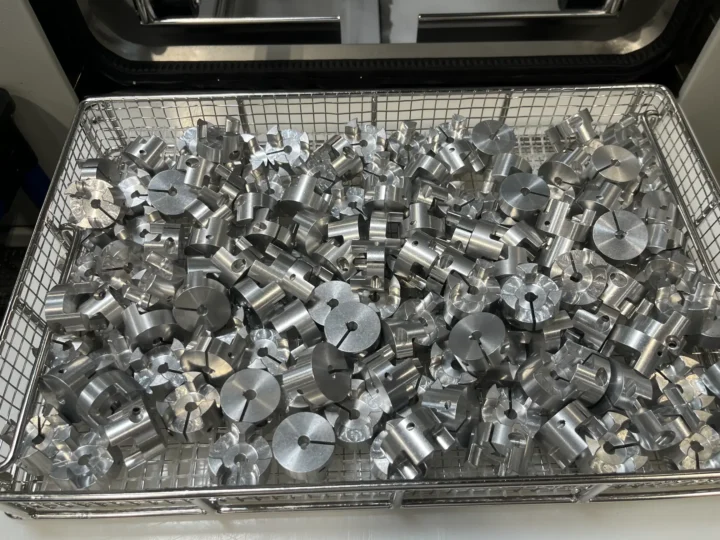

Read MoreQuick Take Isotropic superfinishing is a chemically accelerated finishing process commonly used in aerospace, medical, defense, and automotive component manufacturing where surface finish is critical for proper operation and reliability. Superfinishing can typically achieve Ra values below 0.1 µm (4 µin), and in an optimized process can be reduced to as low as 0.025 µm…

Read MoreInsights M&M Precision Machining won a 250k part per week contract by investing in a new automated parts cleaning process replacing their antiquated manual one. The challenge was the part required a 0.020” hole to be free of oil and debris. Jayco’s HybridClean™ JC 301SC aqueous detergent in the Jayco MAFAC rotary basket washer with…

Read MoreReplacing an open-top vapor degreasing process with an aqueous solution is not only an environmentally responsible choice but also a necessity considering the increased scrutiny placed by the US EPA on solvents like nPB (n-Propyl Bromide), TCE (Trichloroethylene), and Perc (Perchloroethylene). These solvents have been determined to pose an unreasonable risk to human health and the…

Read MoreThe two-step Accelerated Surface Finishing (ASF) process is a specialized surface treatment method used in manufacturing industries to achieve high-quality surface finishes on a variety of parts and components. This process involves the sequential use of JAYCO Chemical Solutions JC 840L as Step 1 and JAYCO Chemical Solutions JC 680B as Step 2, each offering…

Read More