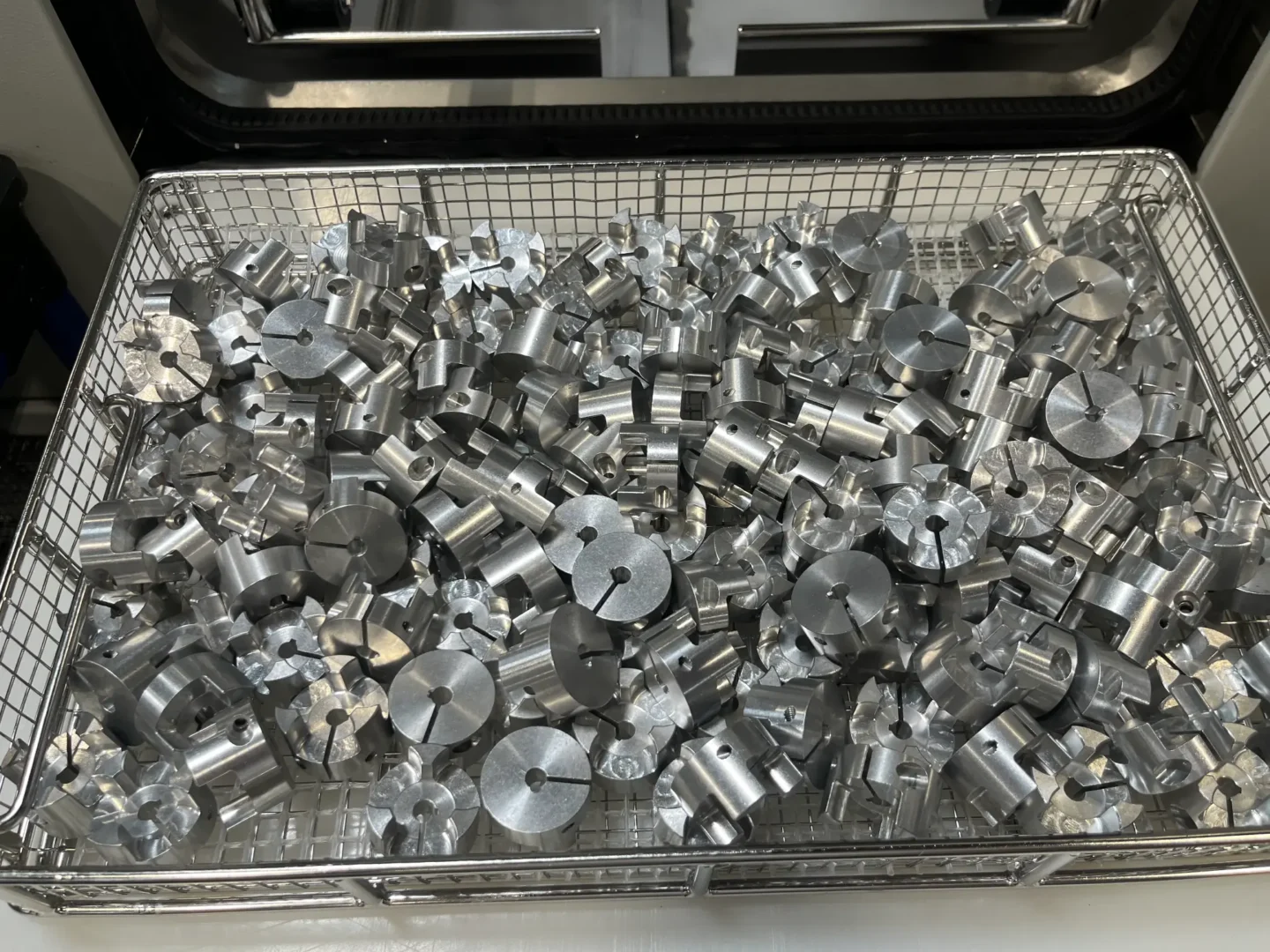

The Ultimate Guide to Ultrasonic Cleaner Solutions for Aluminum Parts

Aluminum is a popular material in industries like aerospace, automotive, and medical due to its lightweight and durable nature. However, cleaning aluminum parts can be tricky. Ultrasonic cleaners have emerged as an effective, non-abrasive solution for maintaining the integrity of aluminum surfaces. In this guide, we’ll cover everything you need to know about ultrasonic cleaner solutions for aluminum—from understanding the challenges to optimizing your cleaning process.

Why Aluminum Needs Special Care During Cleaning

Aluminum’s unique properties make it a go-to material for many applications, but these same properties demand special attention during cleaning. Here’s why:

- Lightweight and Durable: Aluminum is tough yet easy to handle, making it ideal for precision parts. However, it is softer than many other metals, making it more susceptible to mechanical damage such as dents or scratches.

- Chemical Sensitivity: Aluminum reacts negatively to acidic and highly alkaline chemicals, which can lead to corrosion or damage.

- Vulnerability to Scratches: Traditional cleaning methods can leave scratches, reducing functionality or appearance.

Ultrasonic cleaning provides a non-abrasive solution to these challenges, ensuring a thorough clean without compromising the material.

Challenges of Cleaning Aluminum Metals

Cleaning aluminum alloys isn’t without its hurdles. Here are the key challenges you need to be aware of:

Corrosion Sensitivity

Aluminum is prone to oxidation and corrosion when exposed to highly acidic or alkaline environments. Neutral pH or properly inhibited acidic / alkaline solutions are the safest option to remove soils without damaging the material.

Surface Etching

Some cleaning agents can etch or dull aluminum surfaces, compromising their appearance or functionality. Using aluminum-safe solutions with proper inhibitors is essential to avoid this issue.

Cavitation Erosion

Cavitation erosion occurs when cavitation bubbles collapse too forcefully on aluminum surfaces, leaving tiny indentations. This risk is higher at lower ultrasonic frequencies. Using higher frequencies and tailored cleaning solutions minimizes this problem.

Detergent Residue and Rinse Quality

Leftover cleaning agents can cause discoloration, degradation, or chemical reactions. Proper rinsing with deionized water and thorough drying prevent these issues, especially before processes like anodizing.

How Ultrasonic Parts Washers Work

Industrial ultrasonic parts washers use sound waves to create microscopic bubbles in a cleaning solution. This process, called cavitation, generates energy that lifts contaminants from surfaces, even in hard-to-reach areas. Here’s why they’re ideal for aluminum:

- Non-Abrasive Cleaning: No risk of scratches or physical damage.

- Consistent Results: Cleans intricate geometries and hidden crevices uniformly.

- Time-Efficient: Reduces cleaning time compared to manual methods.

Key components of an ultrasonic cleaning line include:

- Wash Tank: Holds the ultrasonic bath solution.

- Transducers: Generate ultrasonic waves.

- Cleaning Solution: Tailored for the material being cleaned.

- Rinse Tanks: Holds water, typically deionized for critical cleaning.

- Drying Unit: Can be hot air, infrared, or vacuum drying.

Choosing the Right Ultrasonic Cleaning Solution for Aluminum

The cleaning solution you use is as important as the ultrasonic cleaner itself. Here’s what to look for:

Proper pH Solutions

Aluminum-safe solutions should be neutral pH or properly inhibited acidic / alkaline to prevent corrosion. Harsh chemicals should always be avoided.

Avoiding Harsh Chemicals

Aggressive agents can cause etching, cavitation erosion, or discoloration. Choose formulations specifically designed for aluminum.

Recommended Solutions

Jayco Chemical offers a range of aluminum-safe cleaning solutions specifically designed for your application and equipment type. These products are tested to remove contaminants like oils, grease, and machining residues without harming the metal surfaces.

Suggested Jayco solutions for aluminum parts in ultrasonic equipment are JC 300C, JC 250C , JC 900, and JC 500 for brightening parts.

Optimizing Ultrasonic Cleaning Parameters

To achieve the best results, it’s important to fine-tune your ultrasonic cleaner’s settings. Follow these guidelines:

Frequency Settings

- Use higher frequencies (e.g., 40 kHz or above) for aluminum to reduce the risk of cavitation erosion. The higher the frequency the less energy that it transferred to the surface of the part.

Temperature Control

- Maintain moderate temperatures (around 50-60°C / 120-140°F) to improve cleaning efficiency without causing thermal damage.

Cleaning Duration

- Avoid prolonged cleaning cycles. Typically, 5-10 minutes is sufficient for aluminum parts.

Best Practices for Cleaning Aluminum Parts

Maximize the effectiveness of your ultrasonic cleaning process with these tips:

Pre-Cleaning Inspection

- Remove heavy contaminants manually before ultrasonic cleaning for optimal results.

Proper Rinsing and Drying

- Rinse thoroughly with deionized water to remove any cleaning solution residues.

- Dry immediately to prevent water spots or oxidation.

Avoid Cross-Metal Cleaning

- Do not clean aluminum parts alongside other metals to prevent galvanic corrosion.

Industry Conformance Testing

- Critical component industries like aerospace require tests such as ASTM F483 for corrosion resistance and ASTM F1110 for sandwich corrosion to evaluate the long-term effects of the cleaning solution. Most chemical manufactures serving the aerospace industry will have conducted this testing to validate performance.

Common Mistakes to Avoid

Prevent damage to your aluminum parts by steering clear of these potential problem areas:

- Overexposure: Prolonged ultrasonic cleaning can lead to surface damage. Stick to recommended cleaning times. Experiment to see what the minimum time required is to achieve your cleanliness level.

- Improper Solution Mixing: Always follow manufacturer guidelines for solution dilution, maintenance, and use.

FAQs About Ultrasonic Cleaner Solutions for Aluminum

Q: Is ultrasonic cleaning safe for anodized aluminum?

- Yes, but it can be tricky to find the right process balance as anodization can vary substantially. Use a proper pH solution and settings for anodized surfaces.

Q: How often should I change the cleaning solution?

- Maintain your tank life by monitoring the pH level and adjusting the dilution per the chemical manufacturer.

Q: Can ultrasonic cleaners remove oxidation?

- Ultrasonic cleaners can remove light oxidation, but heavy oxidation may require additional chemical treatments.

Why Choose Jayco Chemical for Your Ultrasonic Cleaner Solutions

Jayco Chemical develops modern formulations for aluminum-safe ultrasonic cleaning tailored to various industries. With a commitment to quality, safety, and customer satisfaction, our products ensure exceptional results for even the most delicate aluminum parts.

Ready to upgrade your cleaning process? Explore our range of ultrasonic cleaner solutions!